S&T study on heat-resistant materials receives Air Force funding

Posted by Greg Edwards

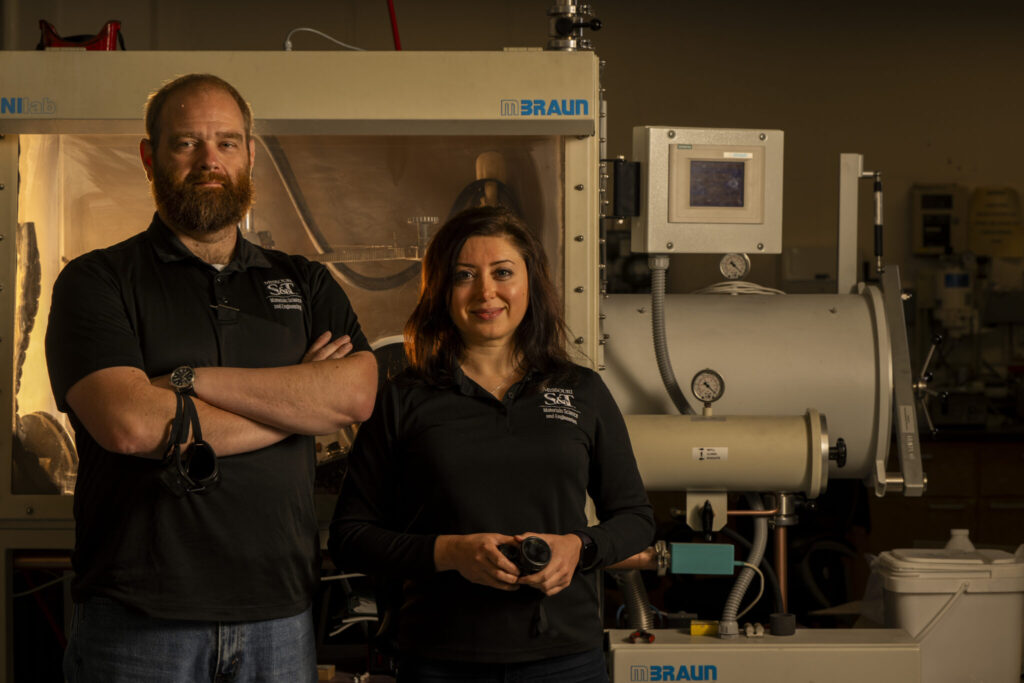

Dr. Arezoo Emdadi monitors plasma arc welding experiment in a controlled-atmosphere glove box. Michael Pierce/Missouri S&T.

Researchers at Missouri S&T are studying advanced materials and welding techniques for use in extreme conditions that could lead to more durable hypersonic vehicles or safer nuclear reactors with funding from the Air Force Office of Scientific Research.

The project supports what the U.S. Department of Defense has deemed a critical technology area for national security.

“We are working to create a reliable welding process for ultra-high-temperature ceramics that enables strong, crack-free bonds, that will make these materials more suitable for use in extreme conditions,” says Dr. Arezoo Emdadi, an assistant professor of materials science and engineering and the project’s principal investigator.

“This research could enable the use of super-strong, heat-resistant ceramics that could potentially lead to more durable hypersonic vehicles, safer nuclear reactors and advanced materials that can withstand conditions where most materials would fail.”

The Air Force provided Emdadi and Dr. Jeremy Watts, an associate research professor of materials science and engineering and co-principal investigator for the project, with over $360,000 for the three-year project, which started last year.

Emdadi says their focus is to study the fusion of silicon carbide-based ceramics with plasma arc welding and how this affects the quality of the materials.

“Changing material microstructures is unavoidable in fusion welding since the process requires heating the material and altering its thermo-mechanical properties,” she says. “There is great value in understanding how the changes that occur impact the mechanical properties and quality of the materials where they are joined together.”

The S&T team will conduct welding experiments with ceramic materials in one of the university’s laboratories, as well as computer models to simulate welding processes and predict how materials will react in extreme conditions and potentially form stronger bonds without defects.

For more information about Missouri S&T’s materials science and engineering programs, visit mse.mst.edu.

About Missouri S&T

Missouri University of Science and Technology (Missouri S&T) is a STEM-focused research university of over 7,000 students located in Rolla, Missouri. Part of the four-campus University of Missouri System, Missouri S&T offers over 100 degrees in 40 areas of study and is among the nation’s top public universities for salary impact, according to the Wall Street Journal. For more information about Missouri S&T, visit www.mst.edu.

Leave a Reply