S&T researchers awarded $13.3 million to zap metal manufacturing’s greenhouse gas emissions

Posted by Greg Edwards

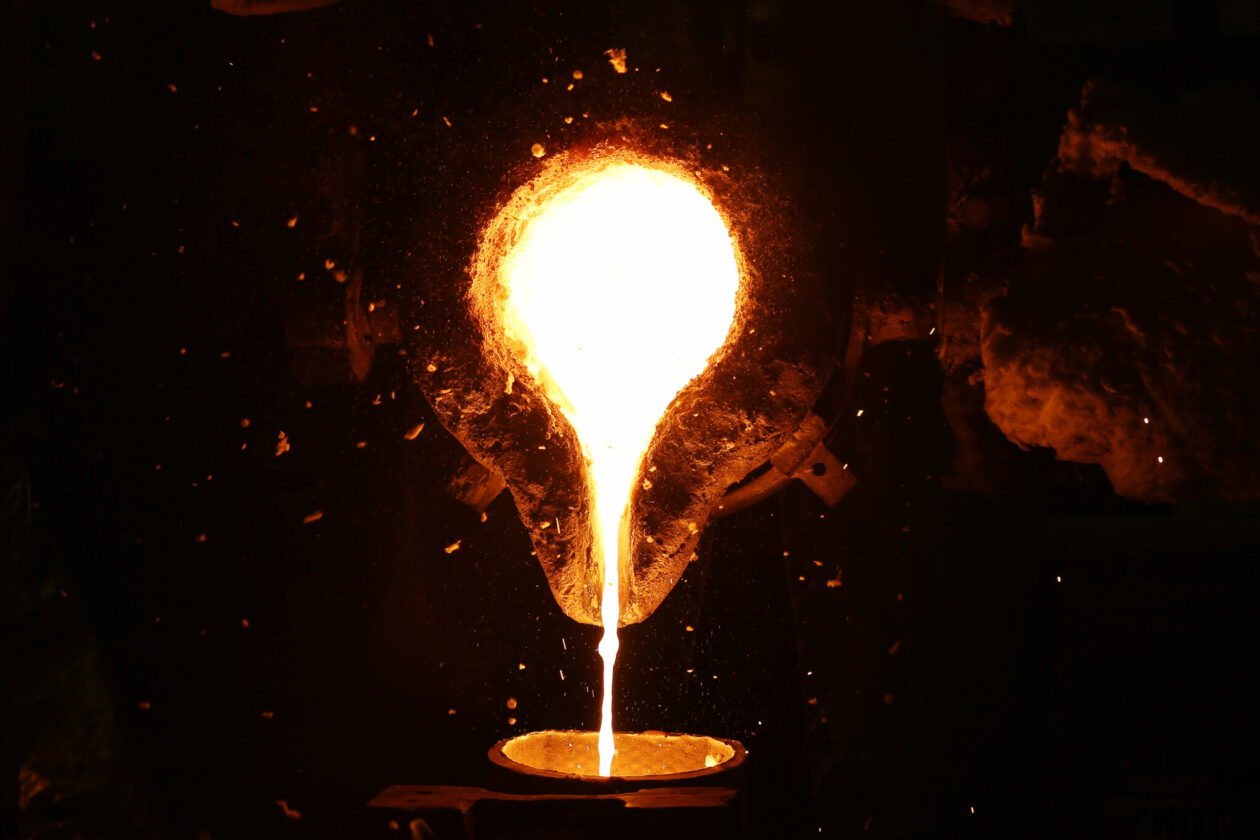

Melting and forging steel requires high temperatures and large amounts of energy, which is achieved through combustion. Missouri S&T researchers plan to lower the carbon footprint by testing alternative methods. Photo by Sam O’Keefe/Missouri S&T.

Researchers at Missouri S&T will receive up to $13.3 million over the next five years through a federal initiative to study methods to lower greenhouse gas emissions in iron and steel manufacturing.

“High temperatures and extreme amounts of energy are required to manufacture these metals, and this currently requires combustion,” says Dr. Ronald O’Malley, the F. Kenneth Iverson Endowed Chair of Steelmaking Technologies and director of the Kent D. Peaslee Steel Manufacturing Research Center at Missouri S&T.

“We plan to demonstrate replacement technologies, which will lead to electrification of these processes,” he says. “The goal will be to determine the most effective processes to significantly lower carbon emissions, while still being economically viable.”

The temperatures necessary for melting and forging steel can reach up to 2,900 degrees Fahrenheit, which is almost 30% of the temperature of the surface of the sun.

Missouri S&T is part of the new Electrified Processes for Industry Without Carbon (EPIXC) Institute, which is under the leadership of Arizona State University. This institute, which has several universities and national laboratories as members, is one of seven Clean Energy Manufacturing Innovation Institutes supported by the U.S. Department of Energy, and it will receive up to $70 million in funding from the agency.

EPIXC’s research will focus on eliminating the need for combustion across a broad range of manufacturing industries, such as iron and steel, cement, food and chemicals.

According to O’Malley, S&T will serve as a testbed for several potential electrified methods for iron and steel work. The university is home to a full-service steel foundry laboratory, hot rolling facilities, and a full-service refractories laboratory. Researchers will use this equipment while exploring concepts such as a microwave-assisted plasma heating system and induction heating, among other approaches.

“This initiative will provide us with the opportunity to develop a facility to test out ideas and accelerate their implementation into industry,” O’Malley says. “Our work should help shape the future of iron and steel manufacturing and significantly lower carbon emissions.”

To learn more about Missouri S&T’s materials science and engineering programs, visit mse.mst.edu.

About Missouri S&T

Missouri University of Science and Technology (Missouri S&T) is a STEM-focused research university of over 7,000 students. Part of the four-campus University of Missouri System and located in Rolla, Missouri, Missouri S&T offers 101 degrees in 40 areas of study and is among the nation’s top 10 universities for return on investment, according to Business Insider. For more information about Missouri S&T, visit www.mst.edu.

Leave a Reply