Partnership among Missouri S&T, Ameren and Hyperion pursues improved energy technology

Posted by Sarah Potter

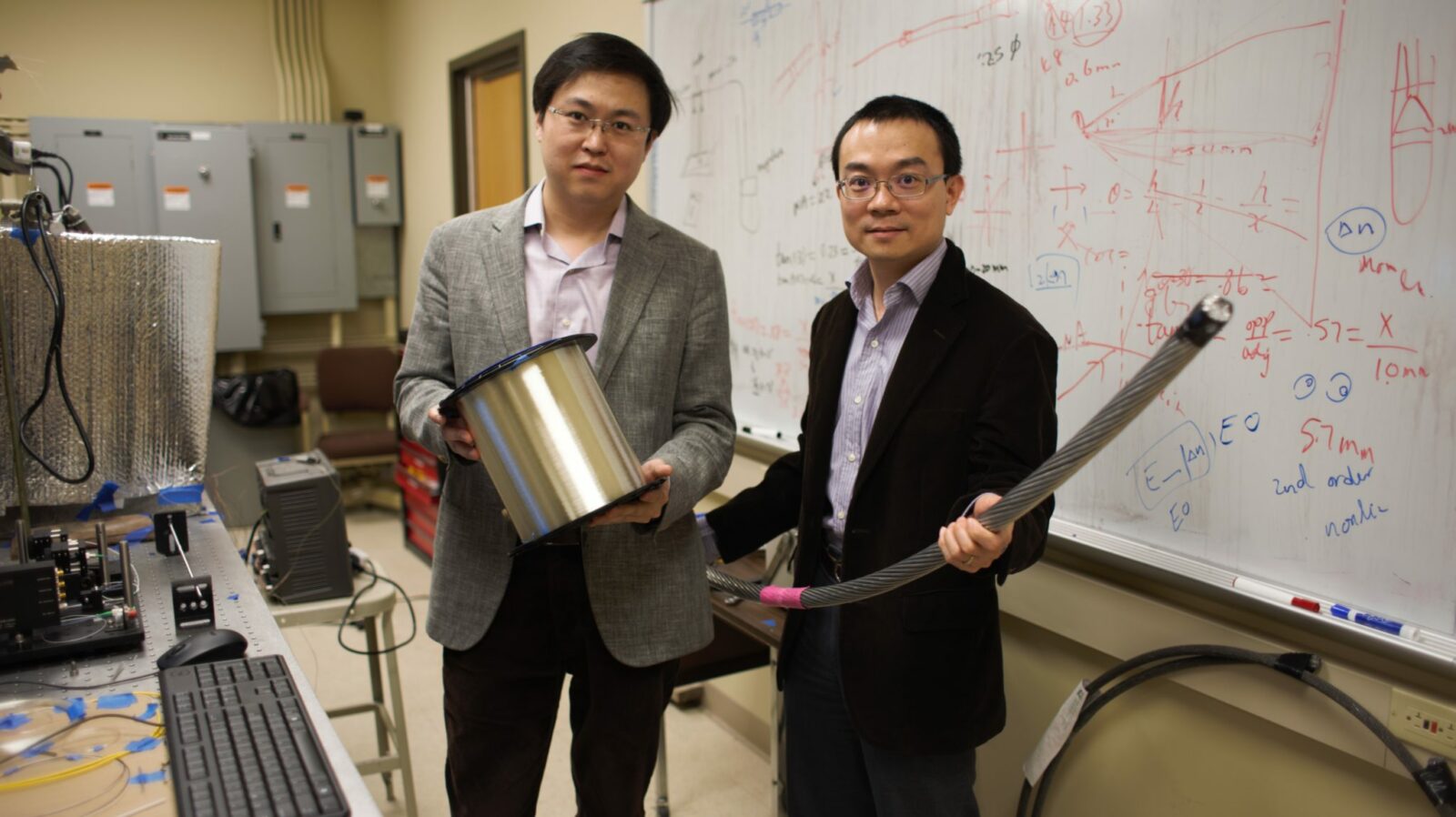

Drs. Jie Huang and Rui Bo, assistant professors of electrical and computer engineering at S&T, holding fiber optic cable and a sample of an electric conductor.

A new partnership among Missouri S&T, a young energy technology company and Missouri’s largest electrical provider could change the way new technology is brought to the market.

Energy giant Ameren Corporation along with Hyperion Inc., a developing technology company in Ontario, Canada, are working with researchers at Missouri S&T to improve the delivery and reliability of electricity services for Missouri customers.

The work centers on using fiber optics to monitor high-voltage power lines and equipment. The research could lead to decreased down times for consumers and cost savings for utilities.

The relationship started when Hyperion was selected to take part in the 2017 Ameren Accelerator program, an innovative public-private partnership with the University of Missouri System, University of Missouri – St. Louis, Accelerate and Capital Innovators. The program assesses, mentors and invests in energy-technology startup companies.

“The Ameren Accelerator makes it possible for companies like Hyperion to find the support and connections needed to transform ideas into actionable solutions that can deliver superior value to our customers, shareholders and the communities we serve,” says Darryl Sagel, vice president of corporate development at Ameren.

S&T faculty serving as subject matter experts on the Ameren Accelerator review committee learned of Hyperion’s work through the program and proposed the partnership for a new energy infrastructure technology. This year, they are working with six new companies and have already introduced them to S&T researchers.

Keith Strassner, assistant vice provost for technology and business development at Missouri S&T, says the Ameren Accelerator allows smaller, more agile companies to develop technology at a faster rate while giving researchers partners for collaboration and commercialization.

At Missouri S&T, Dr. Jie Huang and Dr. Rui Bo, assistant professors for electrical and computer engineering, have been studying how advanced sensor technology could be used for power system applications. Huang met with Hyperion’s Founder, Anselm Viswasam, and shared their research, which shows how fiber optics improve the monitoring of high-voltage power lines. When combined with Hyperion’s technology solutions, fiber optics can monitor high-voltage power equipment.

Drs. Jie Huang and Rui Bo discussing the system used to collect temperature information from the fiber optics.

Hyperion’s fiber optic solutions monitor the different components in a substation or related power infrastructure (such as underground cables) to provide first-hand information on the health and performance of power grids. S&T researchers are using fiber optics to monitor temperature and sagging in electric power lines to better assess how well these high-voltage lines are operating.

Fiber optics may be a better solution for monitoring electrical systems for a number of reasons, say the S&T researchers. Large transformers produce electromagnetic waves, and the pure silica glass in fiber optics mean they are immune to electromagnetic interference, says Huang. The lack of metal makes it a better solution for the power industry, and Huang says the size and shape of the fiber optic cable also allow for more sensitive temperature measurements.

“The fiber optic cable, which is as thin as a human hair, wraps around the winding metal of the transformer. In one millisecond, you can get thousands of temperature readings and the temperature distribution,” says Huang.

Better temperature readings provide a better understanding of power equipment’s performance, as well as a real-time analysis of the equipment’s operation. With this innovation, providers can prevent or fix problems before major malfunctions such as power loss occur. In addition, the readings generated can help increase electricity production, reducing costs and maximizing revenues for the utility operator.

Traditional temperature measurement monitoring means putting sensors at select points on equipment, but the conductor temperature can change along the line due to weather conditions making the line sag and reducing the line capacity, says Bo. A fiber optics-based solution is expected to have a cost advantage over traditional sensors and gives comparable data, he says.

Huang and Bo are now attempting to reduce the cost of the system used to collect temperature information from the fiber optics. The researchers have a patent pending for the system, and Hyperion has signed an 18-month option agreement to license the intellectual property.

“We’re excited to be able to combine our product development and application expertise with S&T’s technology to produce something that will be of significant value to Ameren and utilities like them,” says Anselm Viswasam, president and CEO of Hyperion Sensors. “We believe our partnership will be a model for innovation in the energy/utility sector, and we expect to generate significant economic benefits and high value jobs out of this collaborative effort.”

The next steps include field testing the technology on power lines and transformers as well as commercially packaging the system.

Leave a Reply