Ph.D. student blends disciplines with DOE fellowship

Posted by Nancy Bowles

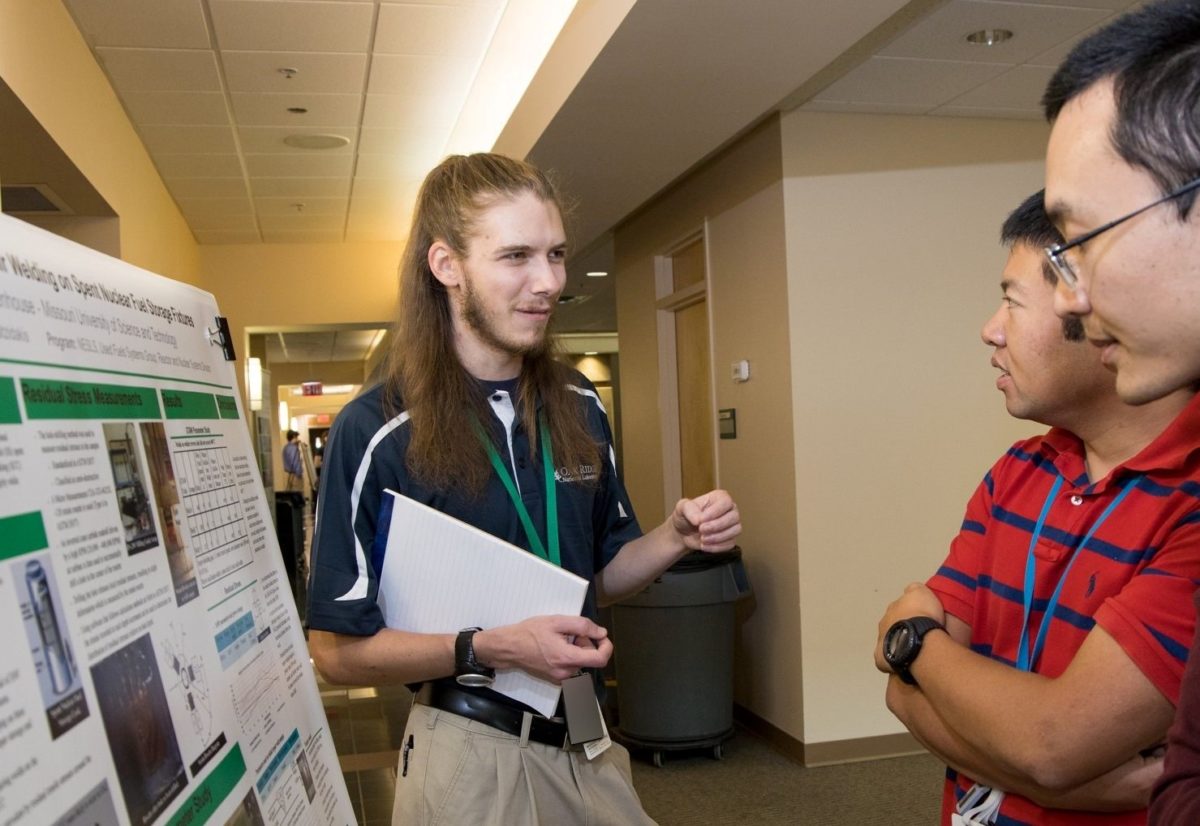

Ph.D. student Joshua Rittenhouse at a poster presentation during his internship at Oak Ridge National Laboratory. Photo provided by Joshua Rittenhouse.

The success of advanced nuclear energy systems depends heavily on the nation’s ability to efficiently manufacture cost-effective, high-quality nuclear components. An Integrated University Program Fellowship from the U.S. Department of Energy will allow materials science Ph.D. student Joshua Rittenhouse to further his research on using additive manufacturing to make silicon carbide-based (SiC) materials for nuclear applications.

“When I started my college career in engineering, I knew that I wanted to be on the cutting edge of science and engineering,” Rittenhouse says. “The fellowship grants me financial stability so that I can focus on my passion for research at an awesome university, in a town that I love, while also continuing to bring my dreams of eventually being employed as a research staff member at a national lab ever closer.”

Joshua is working on the project with Dr. Haiming Wen, an assistant professor of materials science and engineering who has a joint appointment in nuclear engineering.

SiC-based materials are important for components of advanced nuclear systems. Conventional manufacturing can produce high-quality SiC or SiC composite materials, but the manufacturing process is inefficient and costly. In addition, it is difficult to produce components with complex shapes. Additive manufacturing is a promising method for efficiently producing components with complex shapes at a lower cost. The research supported by the DOE fellowship will positively affect the development and deployment of advanced nuclear energy systems in the U.S.

Leave a Reply