Organ-on-a-chip: S&T researchers develop new 3D printing method for tissue engineering

Posted by Greg Edwards

Dr. Anthony Convertine prepares a liquid resin for 3D printing biomaterials used for tissue engineering. Photo by Michael Pierce/Missouri S&T.

A Missouri S&T research team has developed a new light-based 3D-printing method that could speed up and simplify the process of making organs-on-a-chip — small tissue-like devices that are used for medical research and drug testing.

“The human body has about 37 trillion cells, and nearly every one must be close to a capillary to survive,” says Dr. Anthony Convertine, an associate professor of materials science and engineering. “Re-creating those dense microcapillary networks is a major engineering challenge for tissue engineering, but our work offers a path toward overcoming that barrier.”

Convertine says an organ-on-a-chip is usually about the size of a baseball card and lets scientists observe how human tissues respond to new medicines or treatments without testing on animals or people.

He describes the traditional method for 3D printing tissue as building everything point by point in a way that is comparable to an inkjet printer slowly plotting individual dots on a page. This process could be more efficient, Convertine says.

“Point-by-point fabrication works, but it becomes slow and expensive when you try to create the intricate networks of tiny channels that living tissues rely on,” he says. “Our approach uses a light-curable, self-assembling resin that forms sacrificial structures. After printing, we dissolve those structures to leave clean, precise microchannels. It is faster, simpler and easier to scale.”

The method also uses a one-pot approach, combining both the resin that will later be dissolved and the material used to form the chip’s microchannel system into one mixture, which can reduce processing steps and accelerate how quickly labs prototype and test designs.

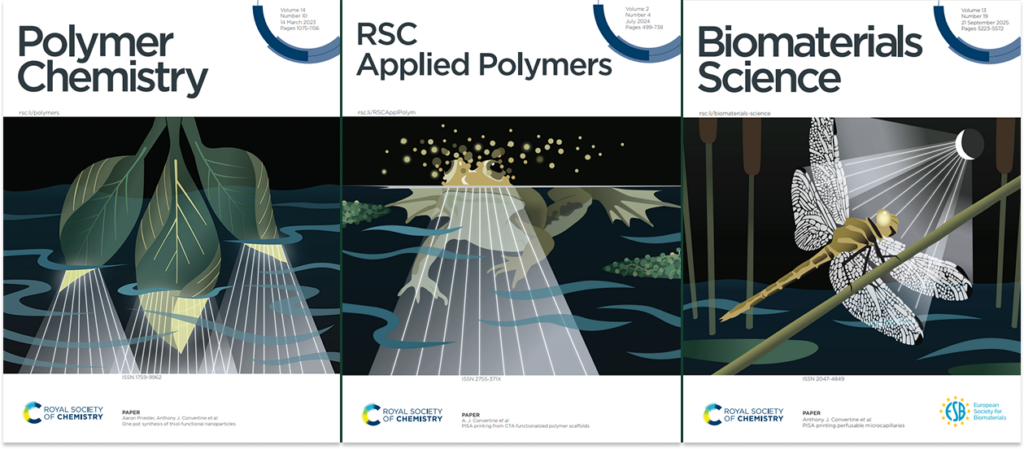

The S&T research was featured as the cover article in a recent issue of the journal Biomaterials Science. This marked the third time since 2023 S&T researchers have been on the cover of one of the Royal Society of Chemistry’s publications with artwork developed by graphic artist Amity Femia.

In 2024, an RSC Applied Polymers cover article focused on how the liquid resin used for high-precision 3D printing could be printed more efficiently and produce stiffer, more crosslinked materials by adding more chain-transfer agent groups, or components that help control how the material forms during printing.

The year prior, a Polymer Chemistry cover article introduced a resin formulation that uses polymerization-induced self-assembly to generate nanostructured networks during light-based 3D printing and support tissue-scaffold applications.

“It is incredibly gratifying to see these three related papers, each building on the last, reach this level of visibility,” Convertine says. “It shows how far our work has progressed and signals even larger advances ahead for 3D-printed materials in tissue engineering.”

For more information about Missouri S&T’s materials science and engineering programs, visit mse.mst.edu.

About Missouri S&T

Missouri University of Science and Technology (Missouri S&T) is a STEM-focused research university of over 7,000 students located in Rolla, Missouri. Part of the four-campus University of Missouri System, Missouri S&T offers over 100 degrees in 40 areas of study and is among the nation’s top public universities for salary impact, according to the Wall Street Journal. For more information about Missouri S&T, visit www.mst.edu.

This is definitely a fascinating and significant approach with future implications. So great to see S&T publications to advertise our developing expertise in a critical field. The covers shown here are beautiful works of art in themselves.

I hope to see future case studies in this field.