Mining engineers to get virtual hands-on experience in new lab

Posted by Mary Helen Stoltz

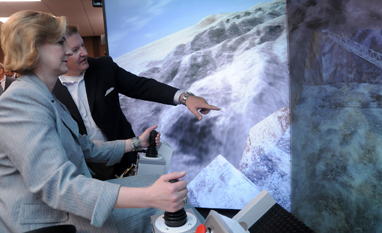

Students in the mining and nuclear engineering department at Missouri University of Science and Technology will soon gain valuable hands-on training in heavy mining machinery, surface mining methods and materials handling systems in Missouri S&T’s new Virtual Surface Mining Facility.

Located in McNutt Hall on the Missouri S&T campus, the 1,400-square-foot facility is the first of its kind in a North American university, says Dr. Samuel Frimpong, the Robert H. Quenon Chair of Mining Engineering at Missouri S&T.

Located in McNutt Hall on the Missouri S&T campus, the 1,400-square-foot facility is the first of its kind in a North American university, says Dr. Samuel Frimpong, the Robert H. Quenon Chair of Mining Engineering at Missouri S&T.

“The lab will introduce students to the world of surface mining,” says Frimpong. “It will give them a chance to interact with large-scale surface mining operations with heavy mining machinery in a classroom environment. We want the students to know that engineers can have fun on the job in their environments.”

The lab was made possible through $675,000 in donations from Caterpillar Global Mining, Luminant Energy, Immersive Technologies and P&H Mining. All of these companies are members of Missouri S&T’s Mining Engineering Development Board.

“We are very grateful to our industry partners for their generous support of this new state-of-the-art facility,” says Missouri S&T Chancellor Cheryl B. Schrader. “We could not provide such a world-class facility without their investment.

“I also want to thank our Mining Engineering Development Board for working with Dr. Frimpong and the mining engineering department to develop a vision of excellence for the department,” Schrader says. “Thanks to this partnership, Missouri S&T will continue to be an international leader in educating mining engineers.”

The Virtual Surface Mining Facility will contain two AES 2B base simulators, one dragline conversion kit and one shovel-dump truck conversion kit.

In addition to educating S&T students, the facility will also allow for industry training and development in surface mining methods and equipment, heavy mining machinery operator skills, risks and hazards control and mitigation, planning and deployment of heavy equipment in rugged terrains, and tracking and improving key productivity indices.

“The virtual facility will sharpen students’ understanding of engineering design associated with heavy machinery and helps them appreciate the magnitude of the challenges associated with these machines,” Frimpong says. “The lab will also sharpen their critical-thinking and problem-solving skills and provide hands-on experience.”

Leave a Reply